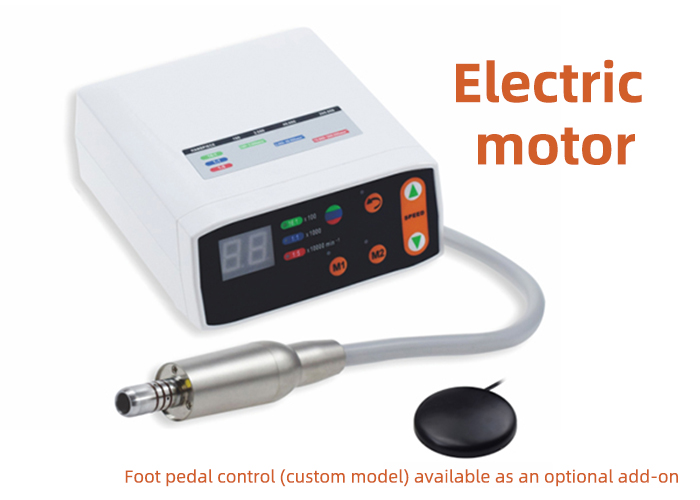

A quiet revolution is unfolding in dental operatories, centered around the evolution of external irrigation electric motors. These systems are no longer just sources of rotary power; they have evolved into integrated hubs of precision, combining illumination, control, and adaptive performance to meet the diverse demands of modern dentistry. The shift towards minimally invasive, patient-comfort-focused treatments demands tools that offer unwavering reliability and exceptional tactile feedback. This new generation of dental electric motor systems answers that call by merging several key technologies into a single, user-centric platform. Their design philosophy prioritizes seamless integration into existing workflows while elevating the standard of care for both routine and complex procedures. From the essential low speed dental handpiece used in caries removal to the high-torque demands of implantology, these motors provide a consistent and controllable foundation.

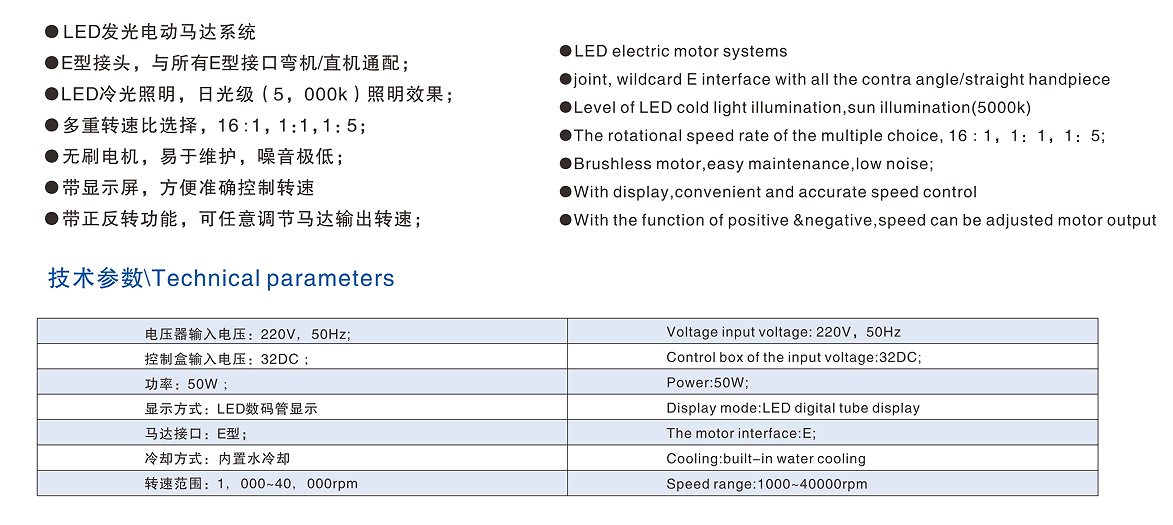

Central to this advancement is the integration of LED cold lighting with a daylight-balanced 5000K color temperature. This illumination standard is critical for procedures requiring exact shade matching and detailed visualization, such as aesthetic restorations or intricate endodontic treatments under magnification. Unlike traditional lighting that can cast shadows or alter color perception, this system provides uniform, shadow-free illumination that reveals true tooth morphology and tissue characteristics. The cold light technology ensures this clarity is delivered without generating heat, protecting sensitive oral tissues and enhancing patient comfort during extended operations. This feature is particularly beneficial when paired with a slow speed dental handpiece for precise finishing work or a slow speed prophy handpiece during meticulous cleaning procedures, where visibility is paramount.

The core of the system's adaptive performance lies in its brushless motor technology. This design is fundamentally quieter and generates less vibration than traditional brushed motors, contributing to a calmer clinical environment—a key factor in managing patient anxiety. The motor delivers consistent torque across a wide speed range of 1,000 to 40,000 RPM, which is managed through an intuitive control interface. The availability of multiple speed ratios (16:1, 1:1, 1:5) allows clinicians to tailor the power output and tactile feel precisely to the task at hand. For instance, a high reduction ratio is invaluable for a dental low speed handpiece requiring high torque for endodontic filing or crown preparation, while a direct 1:1 drive might be preferred for certain surgical applications. The inclusion of forward and reverse rotation further expands procedural versatility, useful for tasks like screw tightening or retrieving broken instruments.

Ensuring this precision control and power is sustainable requires effective thermal management. The built-in water cooling system is a vital component, maintaining optimal operating temperatures even during prolonged, demanding use. This reliability is essential for procedures involving sequential steps or multiple preparations in a single appointment. The motor's universal E-type connection interface offers broad compatibility, allowing it to power a vast array of attachments. This includes not only standard low speed dental handpiece units but also specialized devices like a WBX dental handpiece or a dedicated Dental Implant Handpiece. This interchangeability makes the system a versatile centerpiece in any operatory, reducing the need for multiple dedicated motors and simplifying inventory.

The practical applications of this integrated system span the entire spectrum of dental care. In restorative dentistry, it provides the smooth, controlled power necessary for a slow speed dental handpiece to perform delicate caries excavation or for a high-speed handpiece to achieve precise marginal preparation. In periodontics, a slow speed prophy handpiece benefits from the consistent low-speed torque and clear illumination for effective calculus removal. Its role becomes even more critical in surgical disciplines. For implantology, a dedicated Dental Implant Handpiece relies on the motor's stable performance, programmable speed control, and reversible function for predictable osteotomy preparation and abutment placement. Similarly, the precise control is advantageous for periodontal surgery or apicoectomy procedures.

Ultimately, the value of this advanced dental electric motor system is measured by its impact on clinical outcomes and operational efficiency. The combination of superior illumination, quiet brushless motor operation, and granular precision control empowers clinicians to execute procedures with greater confidence and accuracy. The reduction in noise and vibration directly enhances the patient experience, fostering a more relaxed atmosphere. Furthermore, its adaptive performance and universal compatibility future-proof the investment, ensuring it remains a core asset as techniques and technologies continue to advance. By consolidating multiple critical functions into one reliable unit, this system represents a significant step toward more streamlined, effective, and patient-friendly dental care.