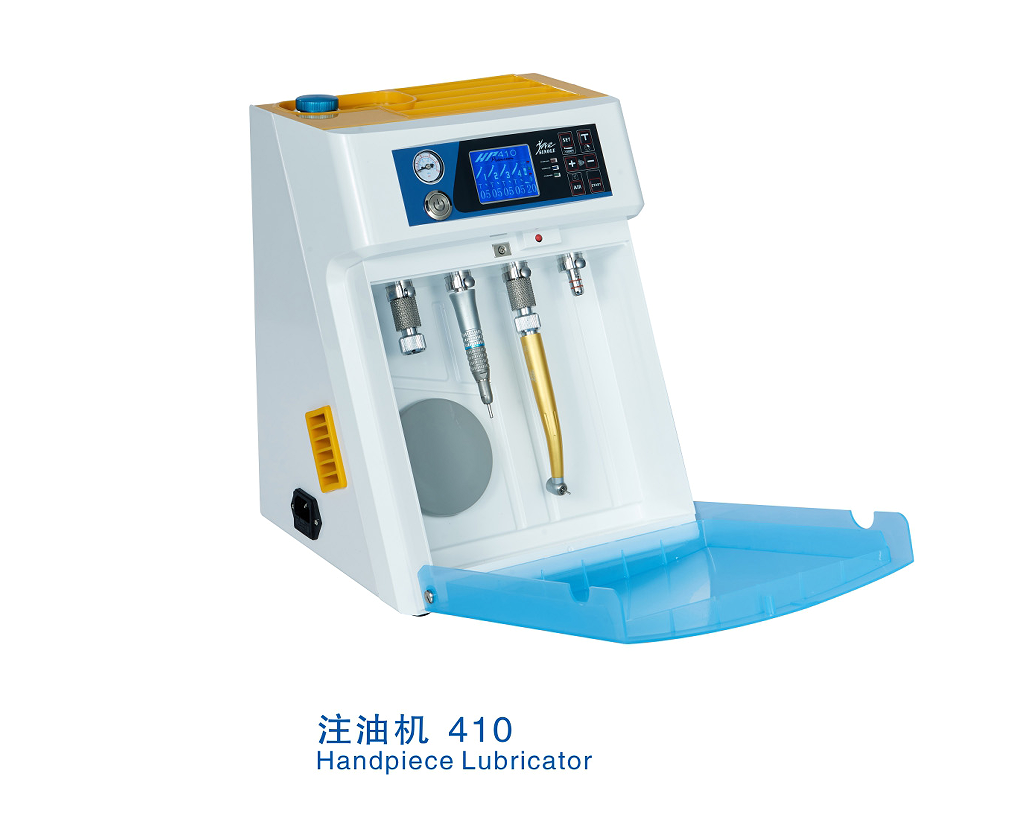

In the modern dental practice, where precision is paramount, the performance of your dental handpieces is foundational to clinical success. These intricate instruments, operating at hundreds of thousands of revolutions per minute, demand consistent and thorough maintenance to preserve their torque, reliability, and longevity. The transition from manual, aerosol-spray lubrication to automated, precision-engineered systems represents a significant leap in clinical equipment management. Professional handpiece lubricators, such as the 410 and 420 models, are no longer optional accessories but essential investments in clinical quality control, infection prevention, and operational efficiency. They transform a variable, messy chore into a standardized, repeatable technical process that directly safeguards your investment and your patients' care.

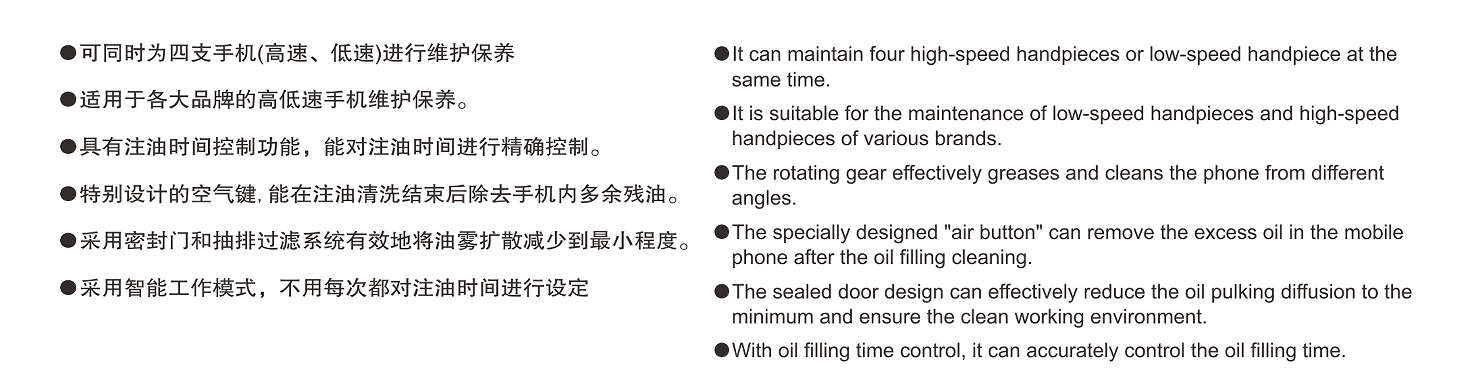

The core value of these advanced maintenance systems lies in their ability to eliminate variables. At the heart of their operation is precise parameter control. The integrated intelligent timer ensures a consistent, measured volume of lubricant is delivered during each cycle, removing the guesswork and inconsistency of manual spraying. Furthermore, these devices operate within a defined and stable working pressure range of 3 to 3.5 Kg/cm². This controlled pressure is critical, as it guarantees that the lubricant fully penetrates the narrowest internal channels and bearings of the high-speed handpiece and low-speed handpiece, achieving complete coverage. The broad operating temperature tolerance, from 5°C to 40°C, ensures this precision is maintained across various clinical environments, providing reliable performance year-round.

Efficiency is seamlessly woven into this design for precision. The capability for four-handpiece simultaneous lubrication is a substantial operational advantage. Clinics can maintain multiple handpieces—a mix of high- and low-speed—in a single, automated cycle, dramatically reducing downtime and streamlining workflow between patients. This batch-processing capability turns maintenance from a bottleneck into a seamless part of the daily routine. Simultaneously, the integrated sealed door and oil mist filtration system address a major downside of traditional methods: environmental contamination. By containing and actively filtering escaping oil mist, these lubricators maintain a cleaner, healthier clinic atmosphere, protecting staff and patients from airborne residues and contributing to superior infection control protocols.

True comprehensive care extends beyond mere lubrication. A defining feature of professional-grade handpiece lubricators is the post-cycle air purge function. After the lubrication and cleaning phases, a powerful burst of compressed air is channeled through the handpiece. This crucial step forcibly evacuates excess oil and cleaning agent from the internal turbines and air/water lines. Preventing this residue is vital; leftover oil can carbonize during subsequent autoclave sterilization cycles, forming abrasive deposits that gradually degrade performance and ultimately lead to premature handpiece failure. Thus, this purge function is not just an add-on but a core component for maximizing the service life of these precision instruments.

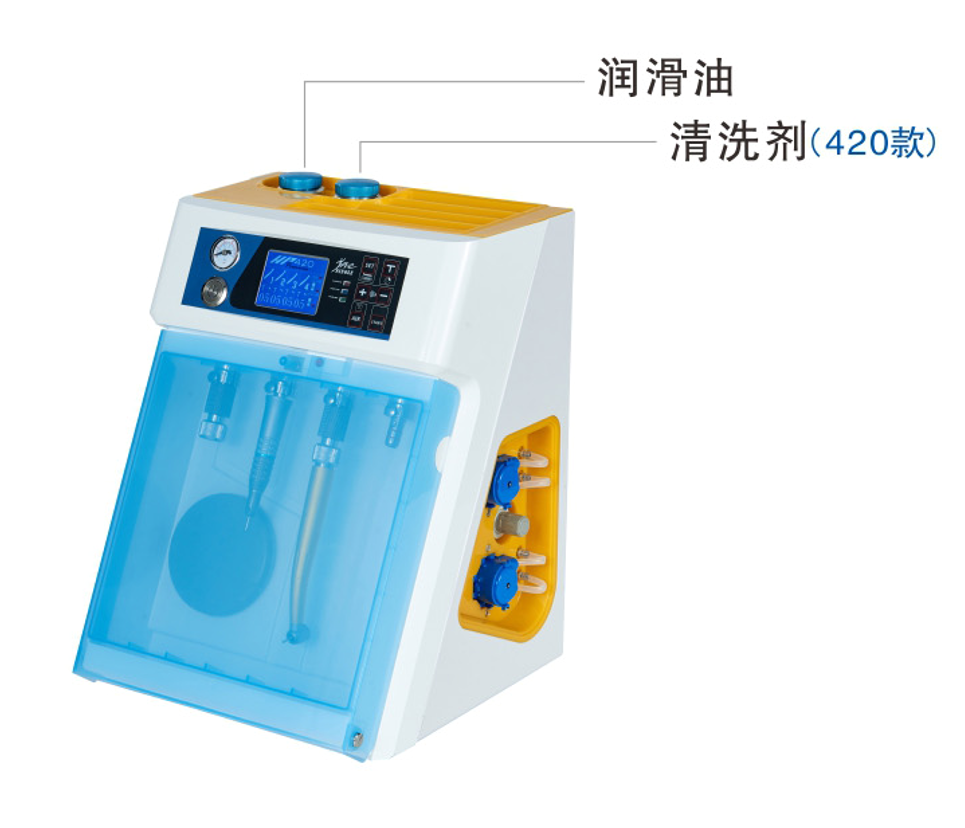

When evaluating options, the 410 and 420 models present tailored solutions for different clinical needs. The 410 Handpiece Lubricator serves as a robust and reliable foundation for daily maintenance, effectively handling the needs of most dental handpiece brands with its efficient lubrication and air purge cycle. For practices seeking an elevated standard, the 420 Handpiece Lubricator offers an advanced step. Its distinct design features separate reservoirs for lubricant and cleaning solution. This allows for a dedicated, two-stage process where handpieces can be thoroughly cleansed of biological debris and cutting debris before receiving fresh lubricant, ensuring even more meticulous maintenance for high-volume practices or those using a wide variety of handpiece models.

Ultimately, integrating a professional automated lubricator into your practice is a strategic decision that supports multiple pillars of a modern clinic. It is a direct investment in asset preservation, extending the service life of expensive handpieces by ensuring they are maintained to manufacturer specifications. It upholds clinical precision by guaranteeing that every handpiece delivers consistent power and speed. It reinforces infection control by enabling a cleaner, more contained maintenance process. And it enhances operational efficiency by saving valuable staff time and enabling faster turnover of essential instruments. In safeguarding the tools of your trade, you ultimately safeguard the quality and trust inherent in every patient procedure.

For any modern dental practice, precision starts with your tools. Investing in a professional automated handpiece lubricator, like the 410 or 420 model, is a direct investment in clinical quality. This smart system delivers precise, consistent maintenance—lubricating, cleaning, and purging multiple handpieces simultaneously—to ensure peak performance, extend instrument life, and uphold the highest standards of care with every procedure.