THE SYMBIOSIS OF POWER AND PRECISION

The modern dental practice is built on a critical partnership: the dental high speed handpiece and its consumable counterpart, the high-speed diamond bur. This combination forms the core of contemporary tooth preparation and surgical intervention. A high speed handpiece, operating at 300,000 to 400,000 RPM, provides the necessary rotational force, but it is the engineered cutting surface of the diamond bur that translates this power into controlled, precise action. The WBX dental handpiece range exemplifies this synergy, designed with advanced ergonomics and turbine technology to deliver stable, vibration-free performance. This stability is paramount, as it allows the clinician to fully utilize the exceptional durability and sustained sharpness of a premium diamond bur. Choosing a system like WBX handpiece with optimized diamond burs is not merely selecting tools; it is investing in a cohesive unit engineered for preparation precision, reduced operator fatigue, and superior patient outcomes. The handpiece is the engine, and the diamond bur is the precisely calibrated tool bit—together, they define the quality and efficiency of countless clinical procedures.

ENGINEERED FOR SURGICAL AND RESTORATIVE DEMANDS

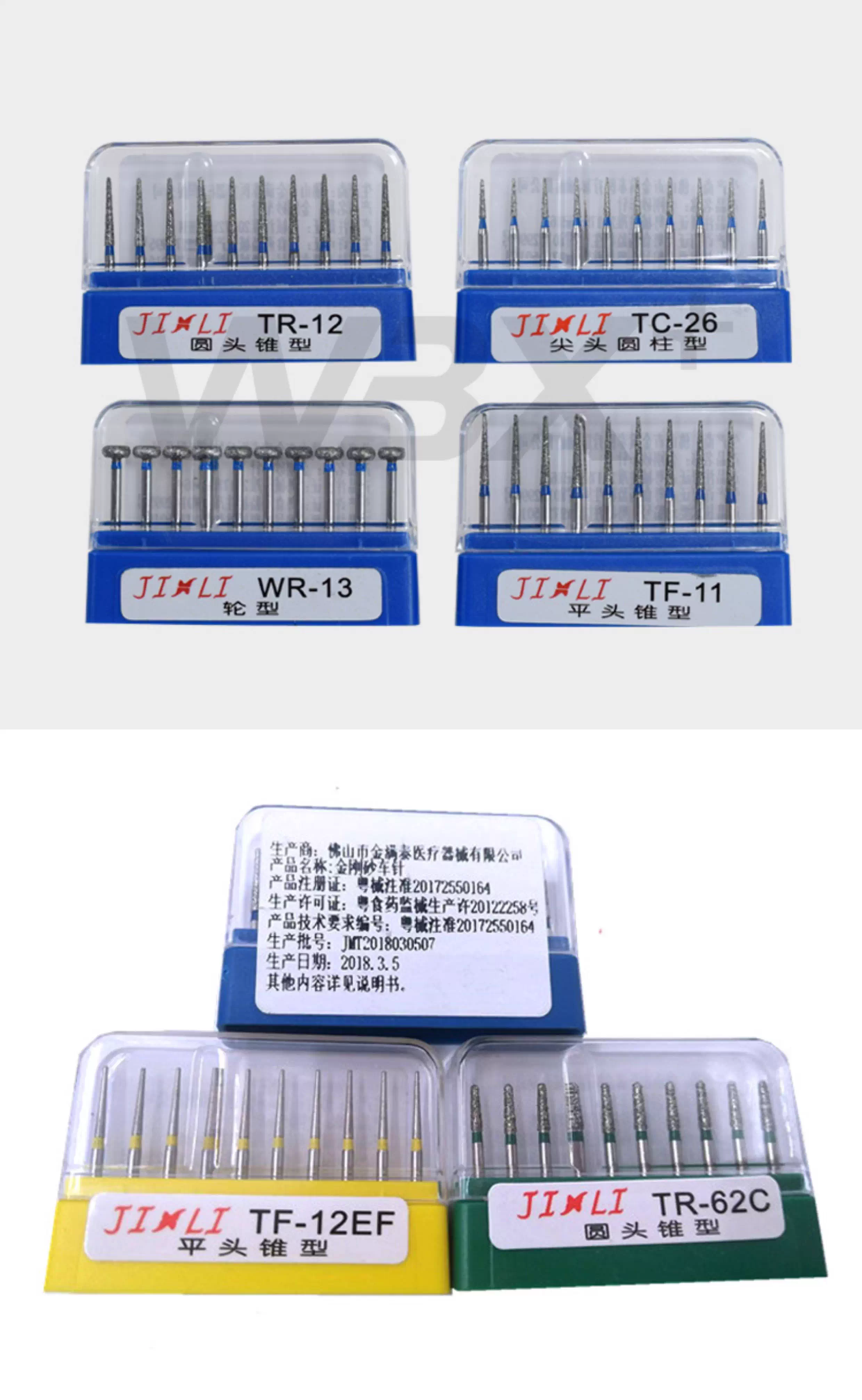

The requirements for a surgical high speed handpiece differ significantly from those of a standard restorative handpiece, and these demands directly influence bur design and performance. A surgical high speed handpiece, such as those in the WBX surgical line, is engineered for higher torque and often incorporates internal or external irrigation channels for critical cooling during osseous surgery. When paired with specialized surgical-length diamond burs, this system allows for meticulous bone contouring in crown lengthening, osteotomy refinement in implantology, and precise sectioning of teeth. The diamond burs used in these applications feature a longer shank, a more robust diamond grit bonding protocol to withstand the tougher osseous substrate, and specific shapes like round or fissure for controlled bone removal. For restorative work, the standard WBX dental handpiece paired with a comprehensive sequence of diamond burs enables everything from gross reduction to margin refinement. The handpiece's consistent speed and minimal run-out ensure that the bur's cutting characteristics—whether the aggressive cutting of a coarse-grit bur or the polishing action of an extra-fine grit—are delivered as intended, ensuring smooth, predictable preparation surfaces every time.

OPTIMIZING THE WBX HANDPIECE SYSTEM FOR CLINICAL EFFICIENCY

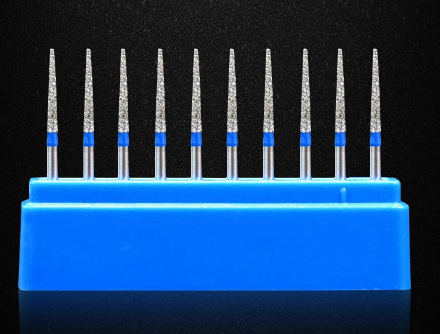

To maximize the investment in a WBX handpiece system, understanding its optimal pairing with diamond burs is key. The WBX dental handpiece is renowned for its balanced weight and concentric chucking mechanism, which minimizes bur wobble. This mechanical precision demands diamond burs of equally high manufacturing quality. Inferior burs with poor grit bonding or unbalanced cores can cause vibration, accelerating wear on the handpiece's turbine bearings and diminishing cut quality. Therefore, using burs with cohesive grit integrity is essential to protect the handpiece's longevity. Furthermore, a logical bur sequence—using a coarse-grit bur in a high speed handpiece for rapid bulk reduction, followed by medium and fine-grits for refinement—reduces the time each bur is engaged with the tooth structure. This not only extends bur life but also reduces the continuous load on the handpiece motor, preventing overheating. For practices utilizing a surgical high speed handpiece, maintaining a separate, dedicated set of diamond burs for osseous surgery preserves their sharpness for bone and prevents cross-contamination, ensuring both the handpiece and the burs perform optimally for their specific, demanding tasks.

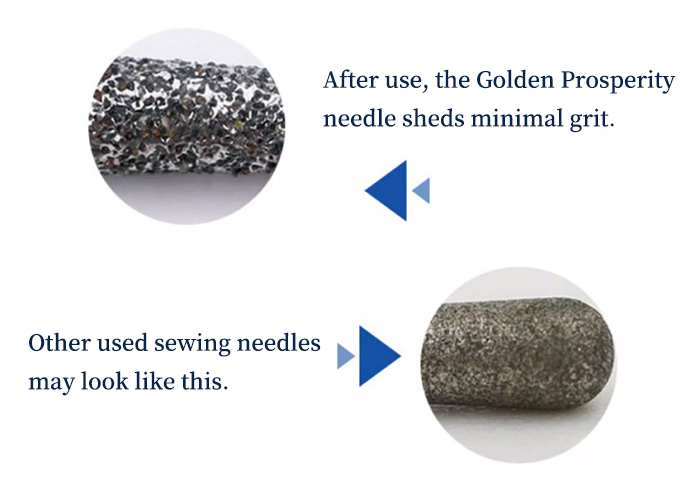

The promise of cohesive grit integrity—the "no-fail" bond—is non-negotiable. It is the foundation of clinical safety and procedural predictability. Modern bonding techniques create a molecular-level union between grit and core, resistant to the tremendous shear forces of high-speed rotation. This guarantees that every particle removed during normal wear is an individual diamond crystal, not a cluster. The result is a clean, predictable cutting action without sudden, catastrophic loss of abrasive material. This integrity ensures the preparation surface left behind is smooth and free of embedded contaminants, which is vital for the optimal bonding of subsequent restorative materials like composites, ceramics, or cements. Therefore, when selecting a high-speed diamond bur, these three attributes must be evaluated as a whole: durability for economics, sharpness for performance, and integrity for unwavering safety.

From its core construction of permanently bonded diamond grit to its vast array of specialized forms, the high-speed diamond bur stands as an irreplaceable pillar of modern dentistry. It is the embodiment of the profession's progression toward minimally invasive, highly precise treatment. Its attributes of exceptional durability, sustained sharpness, and cohesive grit integrity directly translate to enhanced clinical safety, improved patient comfort, and superior restorative outcomes. As the field advances with digital integration and smarter materials, the high-speed diamond bur will continue to evolve, remaining the primary instrument at the cutting edge of dental care. For the clinician, mastering its selection and application is not merely a technical skill, but a fundamental aspect of delivering care that is both scientifically advanced and artfully executed.