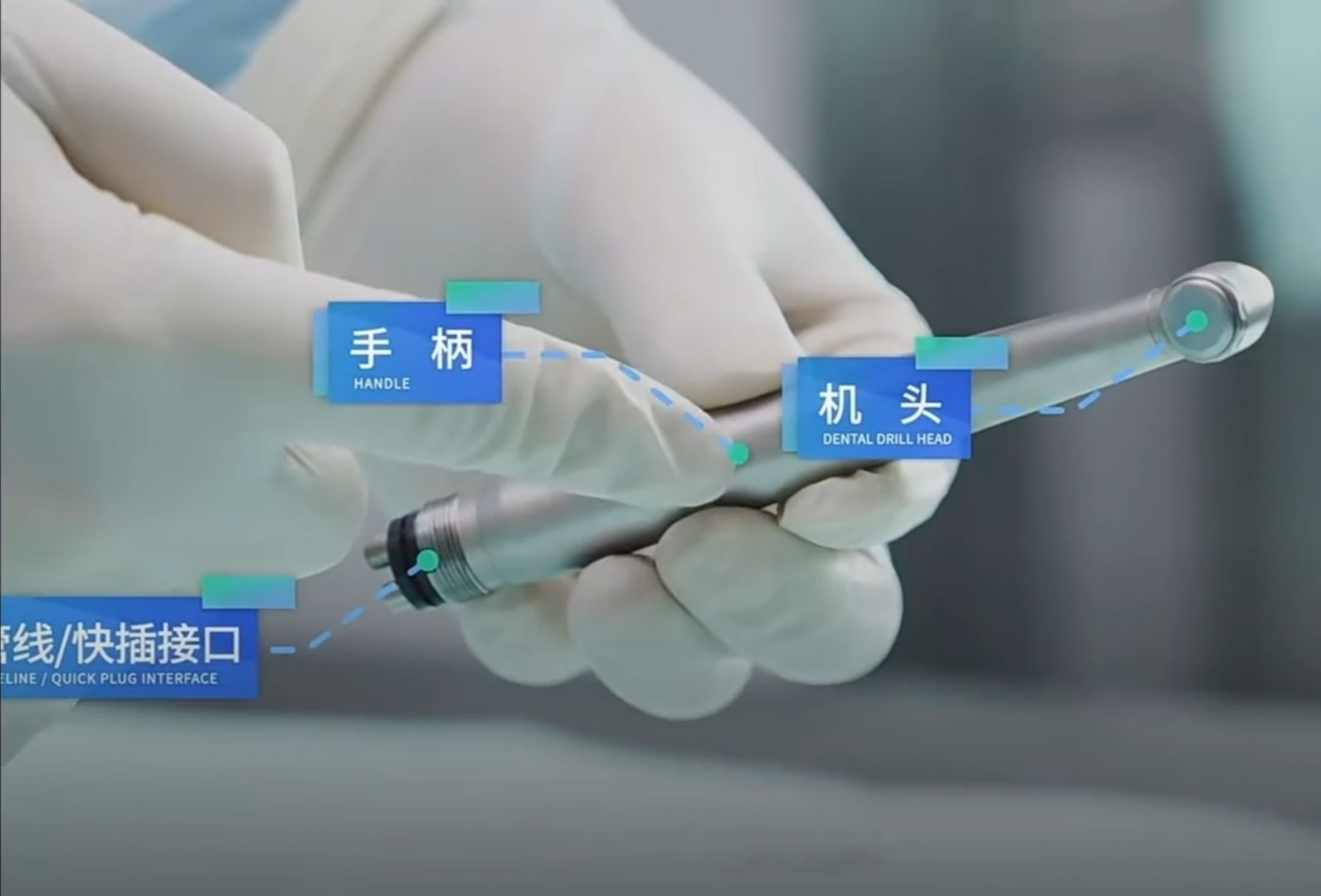

Your Dental Handpiece: A Guide to Care and Sterilization

Your dental handpiece is one of your most critical pieces of equipment. Its performance and longevity are directly influenced by daily care and proper sterilization routines. Following a consistent and careful process helps protect your investment and, most importantly, upholds the highest standards of patient safety. This guide provides general recommendations for the care and sterilization of your dental handpiece. Always adapt these steps to fit your specific clinical protocols and the manufacturer's instructions for your equipment.

Step 1:Immediate Post-Treatment Flushing

The care of your dental handpiece begins the moment it leaves the patient's mouth. To prevent biological debris from hardening inside the intricate internal mechanisms, it is advisable to perform an immediate flush. Keep the dental handpiece running for a short period without a bur installed while spraying air and water. This initial flush helps eject contaminants. Following this, connect the dental handpiece to a dedicated anti-retraction device or use a pressurized cleaning station to further cleanse the air and water lines. Wiping the exterior with a disinfectant wipe completes this first, crucial step.

Step 2:Thorough Cleaning and Debris Removal

A perfectly sterile dental handpiece cannot be achieved without first ensuring it is perfectly clean. Residual proteins and contaminants can shield microorganisms during the sterilization process. For optimal results, we recommend using a enzymatic cleaner designed to break down organic matter. An ultrasonic cleaner is often a gentle and effective method for this deep cleaning, as the cavitation action can reach small crevices. If manual cleaning is your preferred method, always clean under the surface of the cleaning solution to minimize aerosol formation and use soft brushes to avoid damaging the dental handpiece housing.

Step 3: Complete Drying and Visual Inspection

Before moving on to lubrication and sterilization, it is essential that your dental handpiece is completely dry, both inside and out. Moisture trapped inside can lead to internal corrosion and can also impede the steam penetration necessary for effective autoclaving. Use pressurized air to blow out the dental handpiece's lumens thoroughly. Allow it to air dry in a clean environment or use a dedicated drying cabinet. Take this moment to perform a quick visual inspection for any obvious damage and ensure the chuck holds a bur securely.

Step 4: Comprehensive Lubrication is Crucial

This is perhaps the most vital step for maintaining the mechanical integrity and lifespan of your dental handpiece. The high-speed bearings and turbines inside experience extreme forces and temperatures. Proper lubrication with the correct handpiece lubricant reduces friction and protects these精密 components. Using an automated handpiece lubricator is highly recommended. These devices deliver a controlled burst of oil, followed by an air purge, which ensures the lubricant is distributed evenly while expelling excess oil that could otherwise contaminate a patient or impair performance.

Step 5: Proper Packaging for Sterilization

To maintain the sterility of your dental handpiece after autoclaving, it must be packaged correctly. Place the cleaned and lubricated dental handpiece in a sterilization pouch or wrap designed for steam penetration. Ensure the pouch is sealed properly and that the dental handpiece is positioned with the head facing the paper side for optimal steam contact. Clearly label the pouch with the load number, date, and your identifier. This not only keeps the process organized but also ensures traceability, a key component of any clinical quality assurance program.

Step 6: The Autoclaving Process Explained

Steam sterilization, or autoclaving, is the universally accepted method for sterilizing dental handpiece units. It is effective and reliable when performed correctly. When loading the autoclave, ensure the packaged dental handpiece is placed in the chamber with adequate space around it, ideally in a vertical position, to allow steam to circulate freely. Always follow the autoclave manufacturer's guidelines for time and temperature. Common settings for dental handpiece sterilization include 135°C for a minimum of 3 minutes in a pre-vacuum sterilizer. Avoid extended cycle times or excessive temperatures, as this can gradually degrade internal seals and components.

Step 7: Storage and Handling Post-Sterilization

Once the sterilization cycle is complete and the dental handpiece has cooled, handle it with care. Check the external chemical indicator on the pouch to verify that sterilization conditions were met. Store the packaged dental handpiece in a clean, low-humidity, dust-free cabinet. Adhere to a "first-in, first-out" inventory system to ensure that the oldest sterilized items are used first. By respecting the expiration dates on the packaging and maintaining a clean storage environment, you guarantee that a truly safe and ready-to-use dental handpiece is available for every single patient.